Multi axis load cells are becoming more popular and the calibration of such load cells creates various challenges to ensure minimal cross talk and to calibrate each axis of the load cells.

6 axis load cell calibration.

Multi axis load cells are becoming more popular and the calibration of such load cells creates various challenges to ensure minimal cross talk and to calibrate each axis of the load cells.

6 axis load cell calibration.

S bharadwaj reddy april 14 2017 august 22 2019.

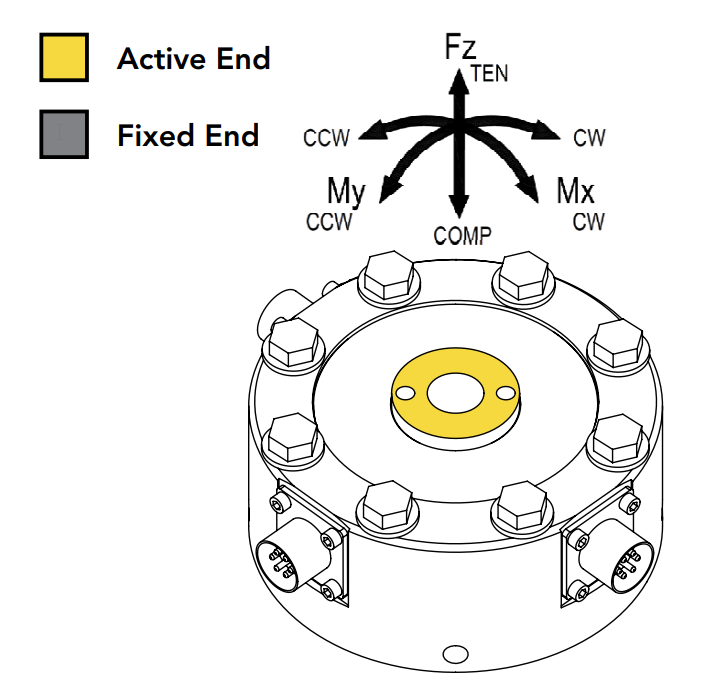

Load cell concept sandia s six axis load cell is an analog device designed to measure the three vector components each of force and torque that can be applied to the cell.

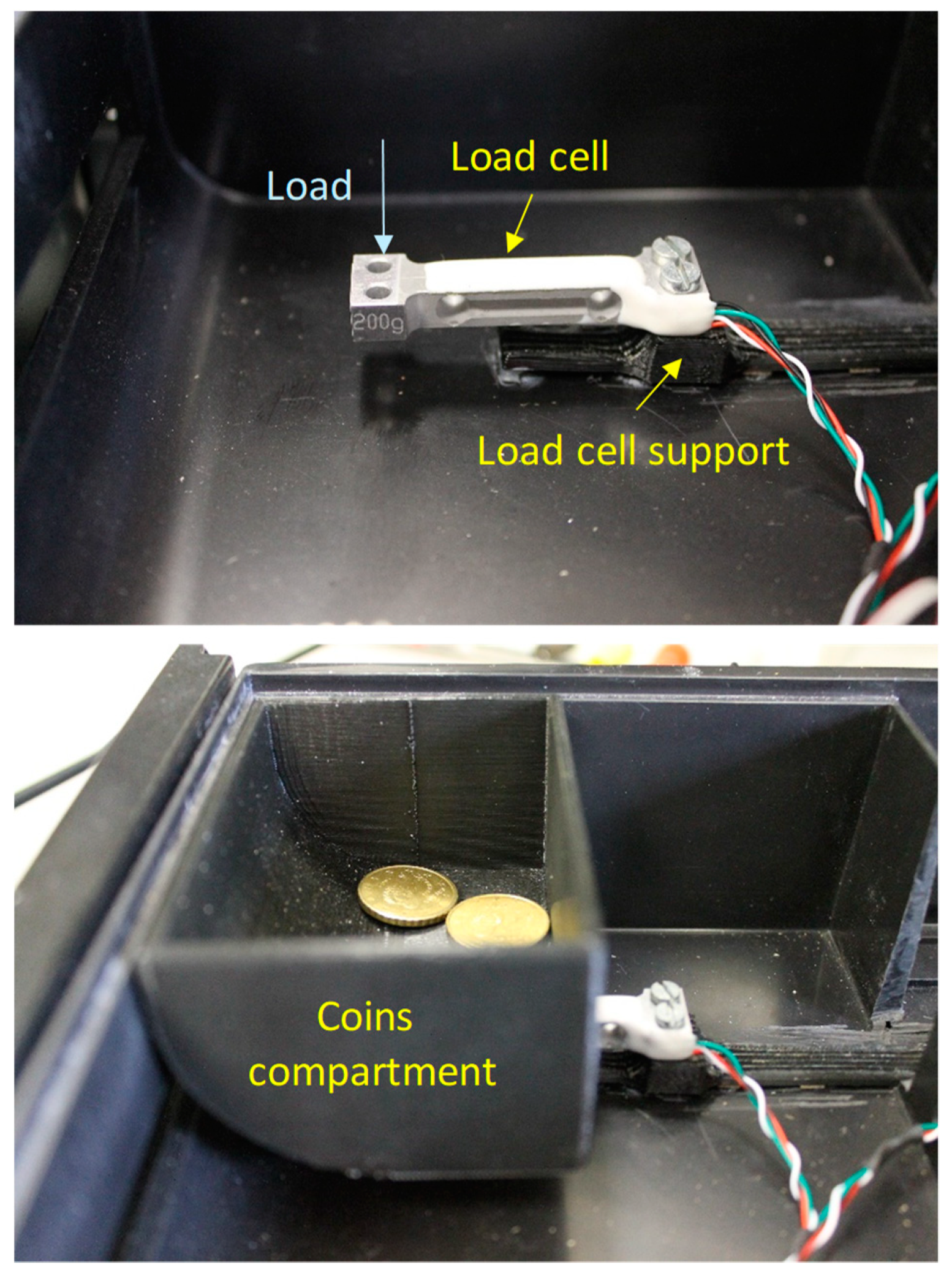

The design and construction of the load cell is very straightforward.

Shunt calibration of a strain gauge load cell.

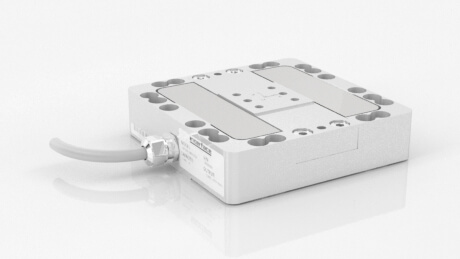

Interface s 6 axis load cell is ideally suited to many industrial and scientific applications such as aerospace robotics automotive and medical research orthopedics and biomechanical.

The michigan scientific six axis load cell tr6d c 40k has the ability to measure forces in six directions meaning it can measure the x y and z axes as well as the rotation around each axis.

The abcs uses load cells hydraulic actuators and a computer control and data acquisition reduction program to automatically generate an extensive balance calibration.

It is capable of simultaneously loading all six balance components to obtain a third order 6 x 96 balance calibration matrix that is more representative of actual in test load conditions than a calibration produced by manual loading.

Six full bridges provide mv v output on six independent channels.

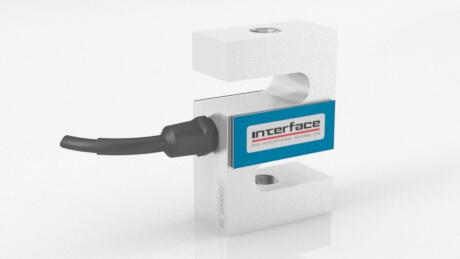

A single point load cell is used to measure forces in a single direction.

For more complex force measurements a multi axis load cell becomes essential for obtaining results.

It consists of a single machined part of simple geometry with strain gauges placed on the surface.

Having the right tools for a job is essential for being able to get the desired results from a test.